Earthing system

Exothermic welding

The solutions of ARGOSWELD ® exothermic welding, from ARGOS®range, will allow you to connect different types of conductors between each other in a sure, reliable, simple and fast way (tape, round, earth rod, rebar, stainless steel).

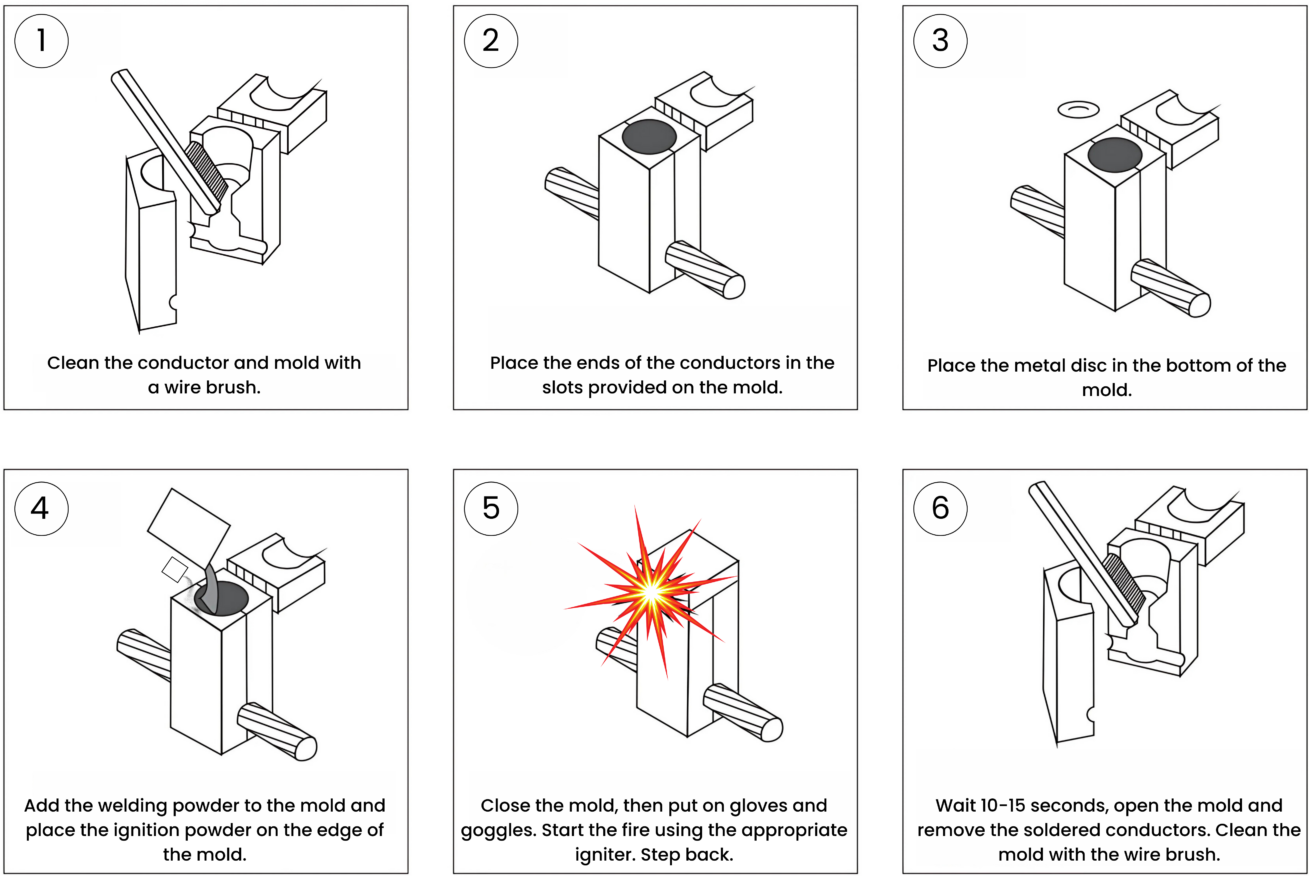

This approach allows to weld the conductors all together in order to obtain a perfect continuity. The principle of exothermic welding consists in putting in a mould the weld powder and the ignition powder.

The composition of the weld powder depends on the metals to weld (copper oxide and aluminum for a welding (copper/copper).

The reduction of copper oxide by aluminum produces under very high temperature, melted copper and slag of aluminum oxide.

This bath of copper in fusion is canalized by the mould on the parts to weld, melt it and link it molecularly between each other.

This system does not need any external power supply. Delivered with suitcase, file, brush, gloves, handle clamp which allows a welding safely.

WARNING :

Wear goggles and gloves

Avoid breathing fumes, which can irritate the respiratory system.

Avoid looking at welding light, which can irritate the eyes.

Avoid contact with hot metal to prevent burns.

Do not use welding in flammable or dusty areas, to avoid the risk of fire or explosion.

Downloadable technical data sheet(s):